Drytec Trans-Canada offers several services related to metal surface finishing. To this end, many of our employees have undergone specific training to carry out the various jobs possible.

Shot-blasting

Shot blasting is the technique of projecting abrasive particles onto the surface of an object to modify its surface structure. The aim of this method is to remove rust, scale and other impurities to obtain a rough surface, preparing the surface before applying a protective layer, such as paint. Steel shot (Grit) is commonly used on raw steel, and is available in different gauges depending on the material to be treated.

A variation of this blasting technique is used specifically to prepare a non-ferrous surface for subsequent coating with a layer of paint. The special feature of this type of shot-blasting is its more delicate approach, adapted to surfaces coated with aluminum or galvanized steel. This method creates an adhesion profile for the paint without altering the thickness of the initial coating. You’ll also find a range of abrasive shot gauges available, depending on the material to be processed.

Anticorrosive paint application

These highly durable paint systems offer robust protection against the effects of time, exposure to the elements, and chemical and corrosive zones. They play an essential role in the long-term preservation of materials, protecting them from internal and external factors that can alter their integrity. Depending on the application or use of a multi-coat paint system, the application of an anticorrosive paint extends the life of an object or structure.

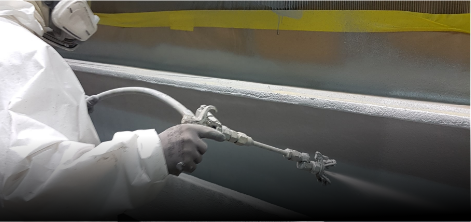

Intumescent coating

Application of a thick coating (PFP) for fire resistance and corrosion protection. The durability of the protection depends on the thickness of the material applied, offering different levels of protection. Certification by the manufacturers is required, as is specific equipment for this application. Applying this protective film to steel parts requires a team of 3 to 7 specialized workers.

Thermal barrier

A thermal barrier is established by applying a substance in aerogel or foam form, with clearly defined characteristics: extremely low heat transfer, protection against corrosion under the covered area, regulation of condensation, establishment of a thermal barrier. What’s more, a top coat can be applied as early as 24 hours after the initial application.

Metallization

Surface treatment involves projecting molten zinc or aluminum particles onto a metal part. Used as an underlying layer, like hot-dip galvanizing, this process creates an extremely effective physical barrier against corrosion. This technique is often used as an alternative when immersion in a zinc bath is not feasible. Whether for large or small parts, metallization offers comparable levels of protection to galvanizing.