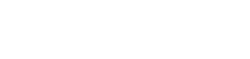

SP-5 / NACE No 1 Metal White

Removal of rust, scale, paint and foreign matter by abrasive blasting.

The surface must be completely free of stains, discolorations or soiling. A completely uniform finish.

Cleaning method down to “white metal” generally used, combined with special coatings, for parts that are immersed or exposed in highly corrosive areas. Our automatic shot-blasting machine with 8 centrifugal wheels is the ideal tool for achieving this preparation on linear structures or pipes.

Equivalence : NACE #1

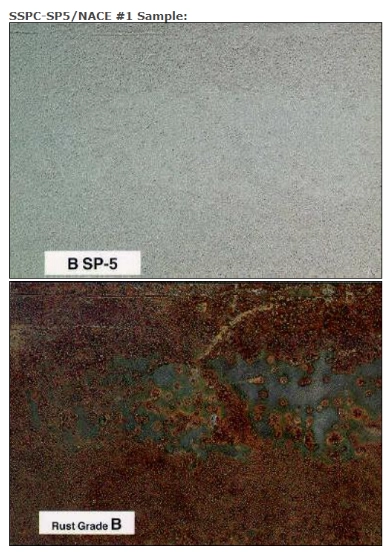

SP-10 / NACE No 2 Almost White

Abrasive blasting to remove all rust, scale, paint and foreign matter, except stains and discolorations.

These very minor stains or discolorations must not exceed 5% of a surface unit determined by the standard.

Methods generally used: manual abrasive blasting and blasting with centrifugal wheels.

Equivalence : NACE #2

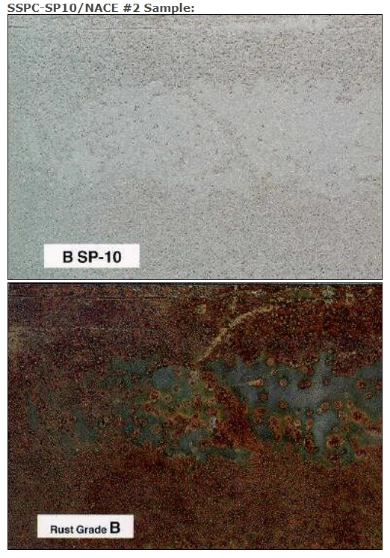

SP-6 / NACE No 3 Sandblasting Commercial

Procedure for removing all rust, scale, paint and foreign matter except stains and discolorations.

However, these minor stains or discolorations must not exceed 33% of a surface unit determined by the standard.

Typical abrasive blasting methods: manual abrasive blasting and centrifugal blasting equipment.

Equivalence : NACE #3

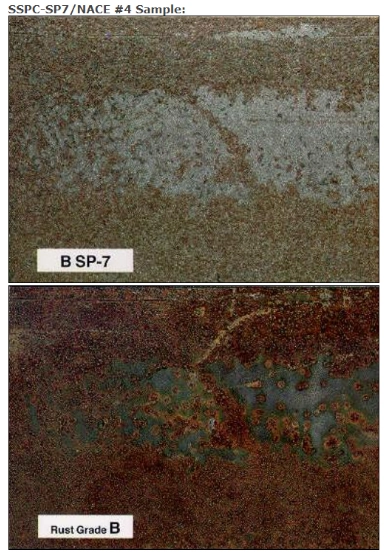

SP-7 / NACE NO 4 BRUSH AND SPRAY CLEANING

Procedure for removing non-adherent foreign matter from the entire surface by blasting with an abrasive.

Scale, rust and firmly adhering paint are permitted.

Typical methods used: sandblasting and sandblasting with centrifugal wheels.

Equivalence : NACE #4

SP - 16

Procedure consisting in creating a slight, uniform surface profile over the entire surface by projecting an abrasive. fine, according to a method and air pressure adjusted to the procedure.

No paint, oil, grease, dirt or dust on the surface is permitted. Before stripping, visible deposits of oil, grease or other contaminants must be removed in accordance with SSPC-SP1 (Solvent degreasing) or other agreed methods.

Intact, well-adhered paints are acceptable on the surface, after a thorough sweeping of the surface, in order to achieve a dense, compliant level of cleaning and roughness.

Method generally used: sandblasting (recycled glass, iron silicate, garnet or other fine non-ferrous abrasives)

Interzinc 315B

Zinc Clad 4100

Galvapak 2K

Perimeprime 394

Tneme-Zinc 90-97

Zinc Rich Inorganic

Amercoat 370

Amercoat 385

Carboguard 890

Carboguard 60

Interseal 670HS

Macropoxy 646

Epoxoline Series 161

Epoxoline Series 66

Chembuilt Series 135

Series N140

Carbothane 134

Interthane 990V

Interthane 870

Acrolon 7300

Series 46H-413